Increase the production and efficiency in your packaging line!

By automating your packaging processes you improve the quality and increase your output.

High capacities and heavy duty operating conditions

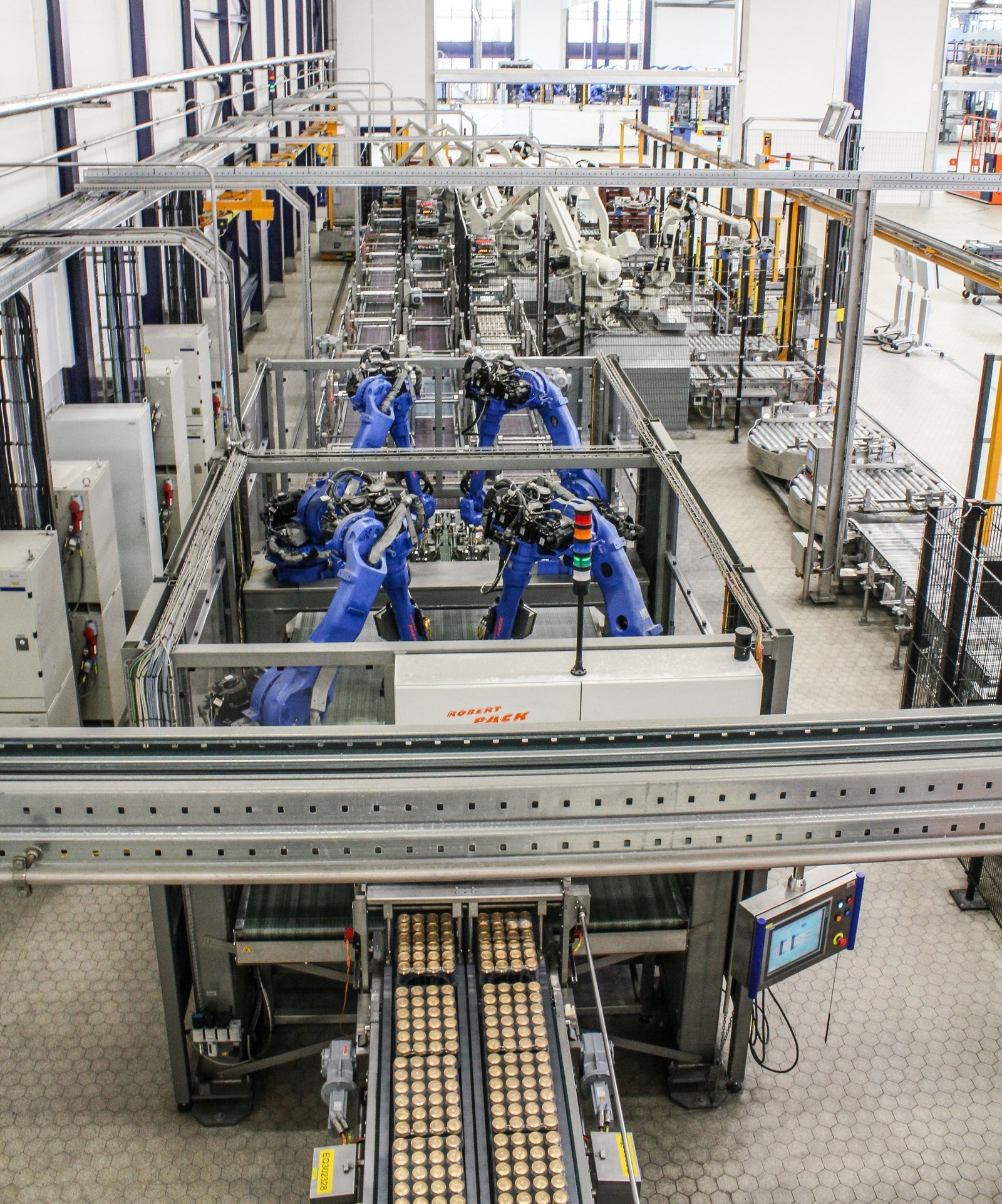

Production lines in the beverage industry are currently running at full capacity. Characteristic thereby are the high capacities and the heavy duty operating conditions. A demanding task that requires a good automation concept in order to be carried out in a flexible and cost-effective manner. Specifically for the processing of products in the beverage industry, our robot automation solutions ensure for a constantly improved quality and a higher production through quicker production processes.

Quick change

Are you looking for packaging machines that can quickly change from one packaging type to another? Then the robotic packaging systems we have developed are the perfect solution! This means that our robots can handle bottles, glasses, cases, tray, etc., and that in many different shapes and sizes.

Products for automation solutions

We offer you smart automation solutions for every phase of your production; from the moment your product is in its primary packaging until the product leaves the company on the pallet.

Reducing operating costs

Many companies have reduced their operating costs significantly by investing in our robotic palletising systems.

Debander robot for the beverage industry

The debander robot locates, cuts and removes plastic straps automatically.

Strap and label (if any) are separated!

While feeding the strap into the shredder, it also checks whether a label is present on the strap. When the shredder detects the label, it cuts it off and separates it from the strap.

The advantage of this is separate waste: one waste stream with straps cut into small pieces and one waste stream with labels. The straps that are cut into small pieces can be recycled.

The complete cycle is repeated until all pre-programmed straps have been removed. At the end of the cycle, the robot checks if all straps have been removed.

The advantages of Robertpack for you as customer:

- More than 45 years of experience.

- A team of experts in our professional field.

- Our own mechanical and software engineering.

- Custom-made and top quality.

- Very good service.

- A solid and reliable partner.

- Solutions from single cells to complete final packaging lines.

Case Bavaria Lieshout palletising installation 100,000 cans per hour

Bavaria has been a Robertpack customer from day one.

Some time ago, we received a request from Bavaria to develop a new robotic palletising system that can palletise 100,000 cans of beer per hour, while allowing for maximum flexibility in terms of the picking, packing and palletising process. The system should be capable of processing about 80 different variations with almost no modifications.