Case study: Zuivelhoeve robotic palletising system

"System meets all expectations"

Some time ago, Zuivelhoeve invested EUR 1.5 million in the automation of its end-of-line packaging process. The palletising robots developed by Robertpack for this purpose satisfy all expectations and the investment is expected to make a return within the next six months.

System description

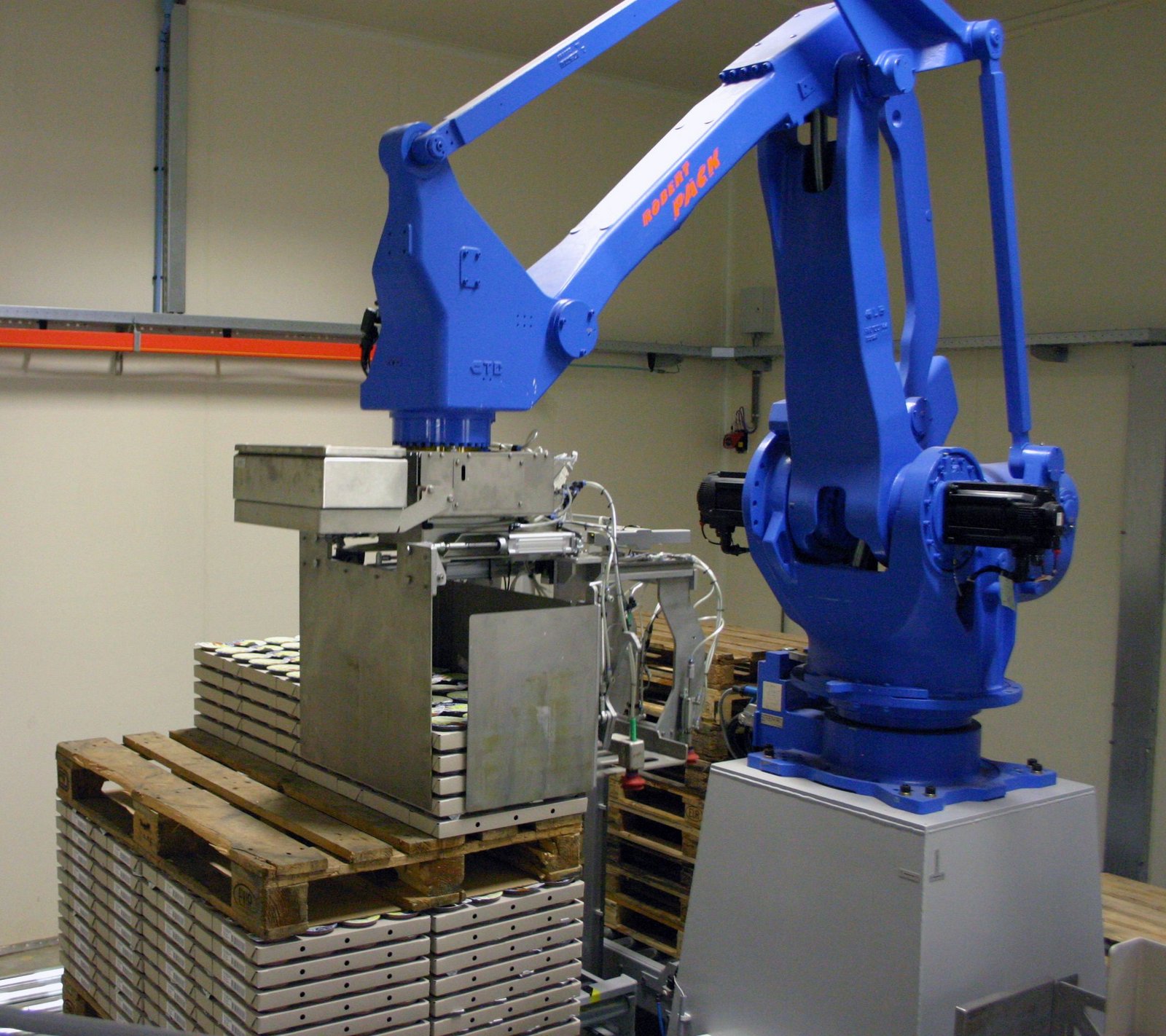

The project involves automatic palletising of trays with dairy products from four (4) production lines using three (3) Robertpack/Yaskawa Motoman 160 kg. robots with DX100 robot control boxes.

The products are taken over from the production machines on the product roller conveyor system. The products are then transported to three robot cells.

Universal fork gripper

Due to the high capacity, the products are stacked before they are transported into the robot cell, where a universal fork gripper picks up the products at the pick point and places them on the pallet according to a pre-programmed stacking pattern. The robotic gripper is also suitable for placing pallets and layer pads.

When the pallet is ready, it is automatically discharged. The robot then takes a new pallet and places it onto the stacking position. When pallets are to be doubled (up to four pallets on top of each other), the robot will first place a top sheet on the full pallet and then stack a pallet on top of it and proceed to load the second pallet.

Double traverse carriage

When it is ready, the doubled pallet is discharged to the buffer position. Up to two stacks of empty pallets are then transported as a complete stack of pallets from two (2) buffer conveyors through a double traverse carriage to the robot cell.

The full pallet is conveyed by means of the same double traverse carriage to the pallet removal position. The pallet must be removed by means of a forklift truck.

The operator selects the operations to be performed and the products to be palletised and the associated stacking patterns from a Siemens 10" HMI.

Advantages from using Robertpack robot depalletising system

- Modular robot cell

- Highly efficient and economically attractive solutions

- Tailor-made solutions

- Very flexible with minimal changeover time

- High capacity and efficiency

- Reliable with minimal maintenance costs

- 4, 5 and 6-axis robots with payload capacities of up to 1,200 kg.

- For trays with or without shrink film, crates, cases, loose cans, bags, pails, etc.