Robertpack COBOT Palletising Solution

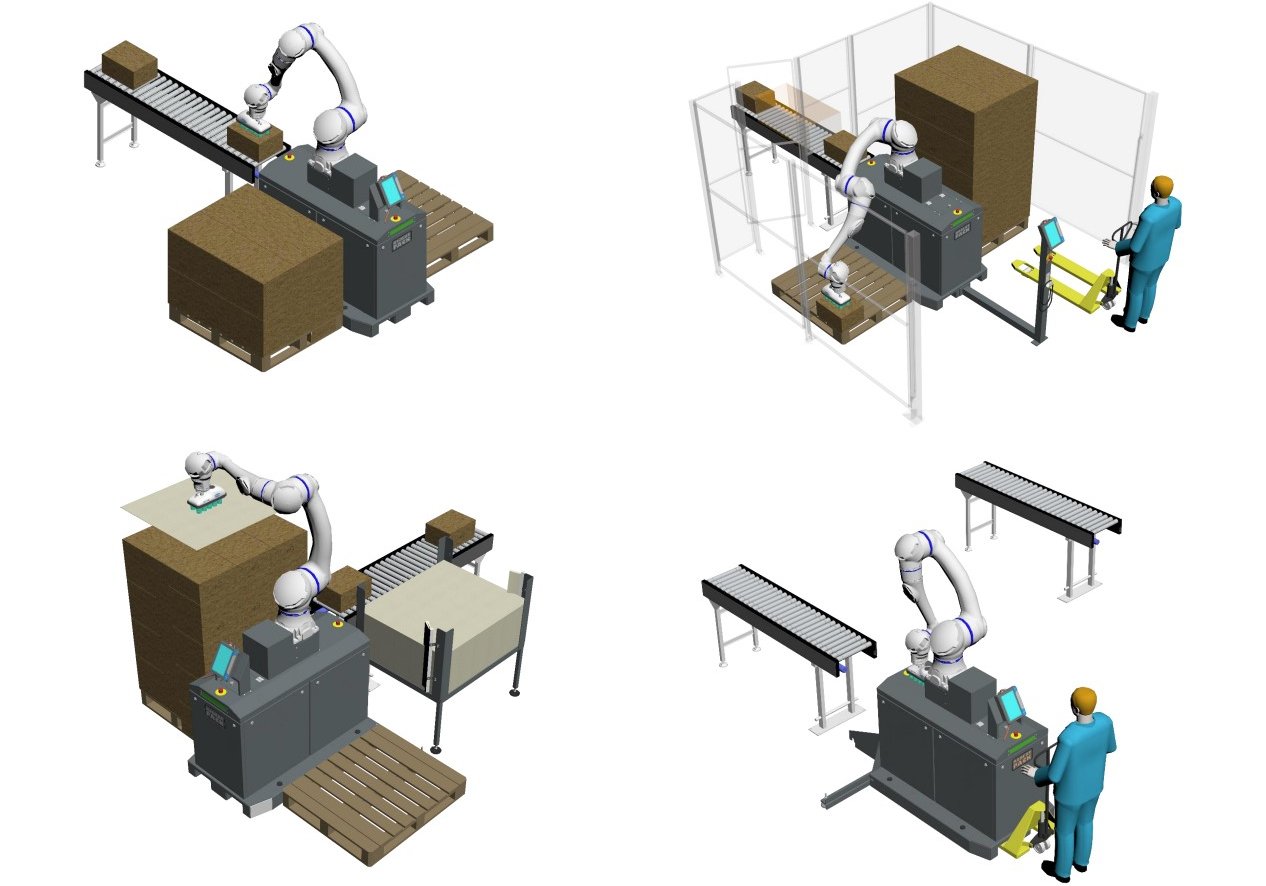

Our COBOT (de-)palletising solution is flexible, easy to install/program, and sustainable.

Our industrial COBOT palletising solution is readily available and equipped with a 6-axis YASKAWA HC cobot that boasts superior payload capacity of up to 30 kg. Of course, a FANUC COBOT is also an option.

Robertpack's industrial COBOT palletising solution operates collaboratively and can stack products onto pallets safely and completely automatically, without the need for fencing. It can achieve standard stacking heights of up to 2.2+ meters (optionally higher), and with a high IP67 protection rating, it can also be employed in food-related applications.

Our COBOTS maintain the same quality as our industrial ROBOTS and can be serviced by ROBERTPACK as part of the complete solution. ROBERTPACK solutions are designed to last for a minimum of 10, 15, or even 20+ years without compromising technical availability and OEE.

In summary, ROBERTPACK offers both traditional industrial and collaborative solutions, both of very high quality (YASKAWA or FANUC), while ensuring the technical availability/OEE that you can expect and are accustomed to from ROBERTPACK.

**Safety is a top priority at Robertpack, whether it's in traditional industrial robot applications or COBOT applications. In the case of COBOTS, safety is an additional focus due to their collaborative nature, often used without safety fencing.

The Robertpack team is ready to provide you with guidance!

Benefits of the Robertpack COBOT Palletising Solution:

- Largest cobot in its class with a payload capacity of up to 30 kg and a height of 2.2+ meters (optionally higher)

- Operates without screens thanks to internal torque sensors

- Fast cycle times, even in collaborative mode

- Advanced safety features

- Standard IP67 rating and food-grade lubrication for sensitive environments such as the food industry