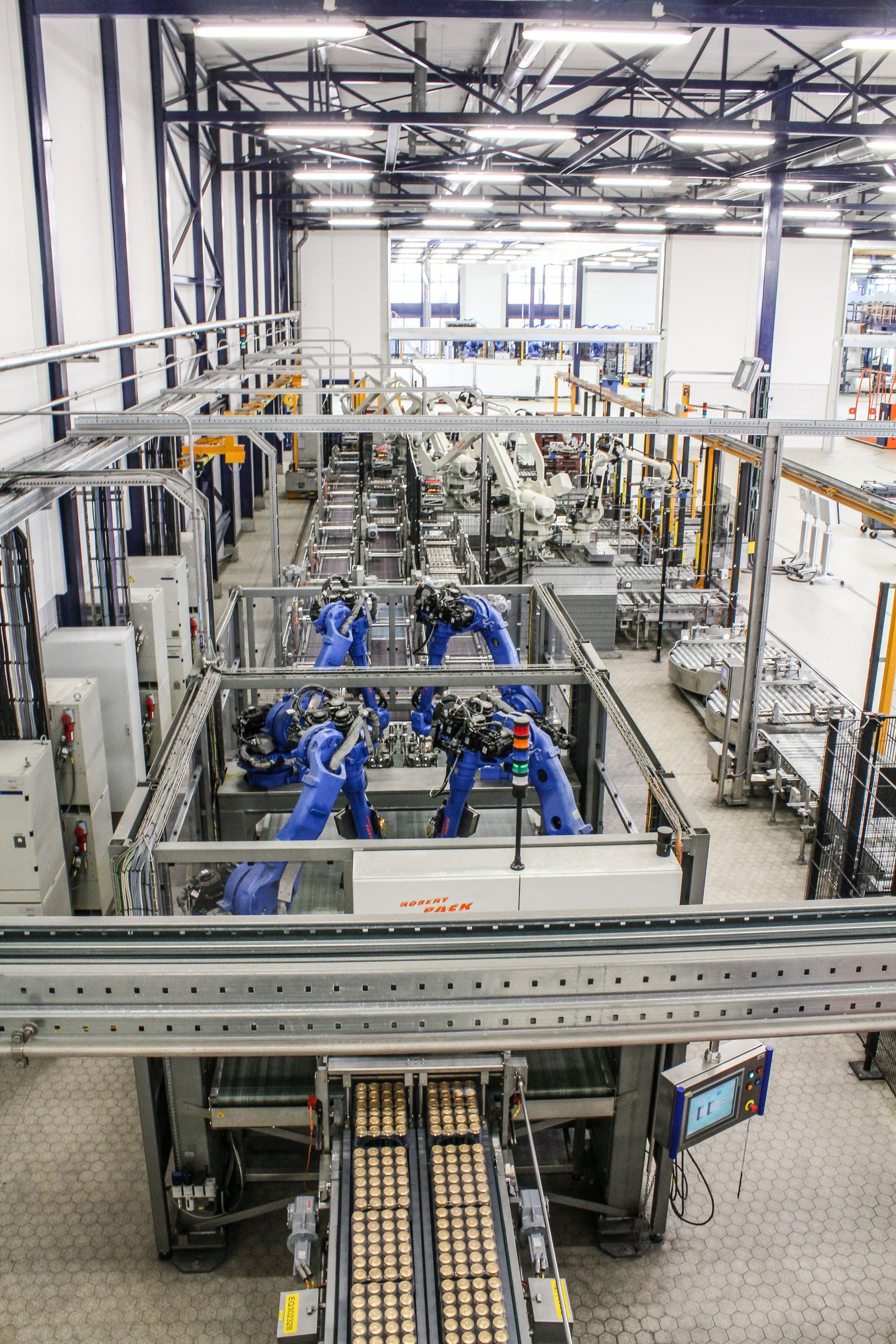

Case study: Bavaria Lieshout palletising system

100,000 cans per hour

Bavaria has been a Robertpack customer from day one. Some time ago, we received a request from Bavaria to develop a new robotic palletising system that can palletise 100,000 cans of beer per hour, while allowing for maximum flexibility in terms of the picking, packing and palletising process. The system should be capable of processing about 80 different variations with almost no modifications.

Situation

The infeed of beer cans to the system occurs via two conveyors, Here four YASKAWA MH50 robots supply foil packs filled with 4, 6, 8, 12, 18, 24 or 30 cans to the distribution stations. The beverage cans have the same diameter with a volume of 0.33, 0.4 or 0.5 litres. The YASKAWA robots achieve 100% process reliability with this station.

From this station, the beer cans then reach three palletising stations, each of which is equipped with a YASKAWA MPL160 robot. The three high-speed 4-axis robots control up to three of the nine conveyors. This is where the actual palletising takes place. Stacking on the pallet is done in record time. Each robotic gripper can handle up to 72 cans, regardless of the packaging type. During the processing of 4-packs, the robot must handle a total of 18 packaging units at a time. Our engineers have designed a flexible gripper with mechanical and pneumatic components, allowing each packaging type to be processed by a single gripper. Thus, the grippers do not need to be exchanged, which saves a significant amount of time.

Placing layer pads

Every large YASKAWA palletiser is assisted by a smaller MPL80 palletising robot. These robots are only used when interleaving of the different packaging types by a cardboard layer pad is required. The MPL80 Robots take the layer pads from a pallet and place them quickly and reliably at the desired location.

Fast adjustment with the press of a button

A different packaging size is selected on a regular basis. To do so, the operator selects the right type with a press of the button on the control panel and the adjustment is made.

Advantages from using Robertpack robot depalletising systems:

- Modular robot cell.

- Highly efficient and economically attractive solutions.

- Tailor-made solutions.

- Very flexible with minimal changeover time.

- High capacity and efficiency.

- Reliable with minimal maintenance costs.

- 4, 5 and 6-axis robots with payload capacities of up to 1,200 kg.

- For trays with or without shrink film, crates, cases, loose cans, bags, pails, etc.