We ensure and increase the efficiency and continuity of your robotic system!

We perform maintenance to prevent unexpected downtime as much as possible and to ensure the efficiency and continuity of your production. In addition, we are convinced that the life of your system is dramatically increased if maintenance is carried out regularly and correctly.

(Periodic) inspection

The inspection of the machines and systems not only extends to safety but also to the reliability of the machines and systems. This prevents unexpected downtime; hence the commercial importance of such inspections. Our technicians evaluate the technical condition of your machine and provide you with appropriate advice about the options to ensure and improve efficiency.

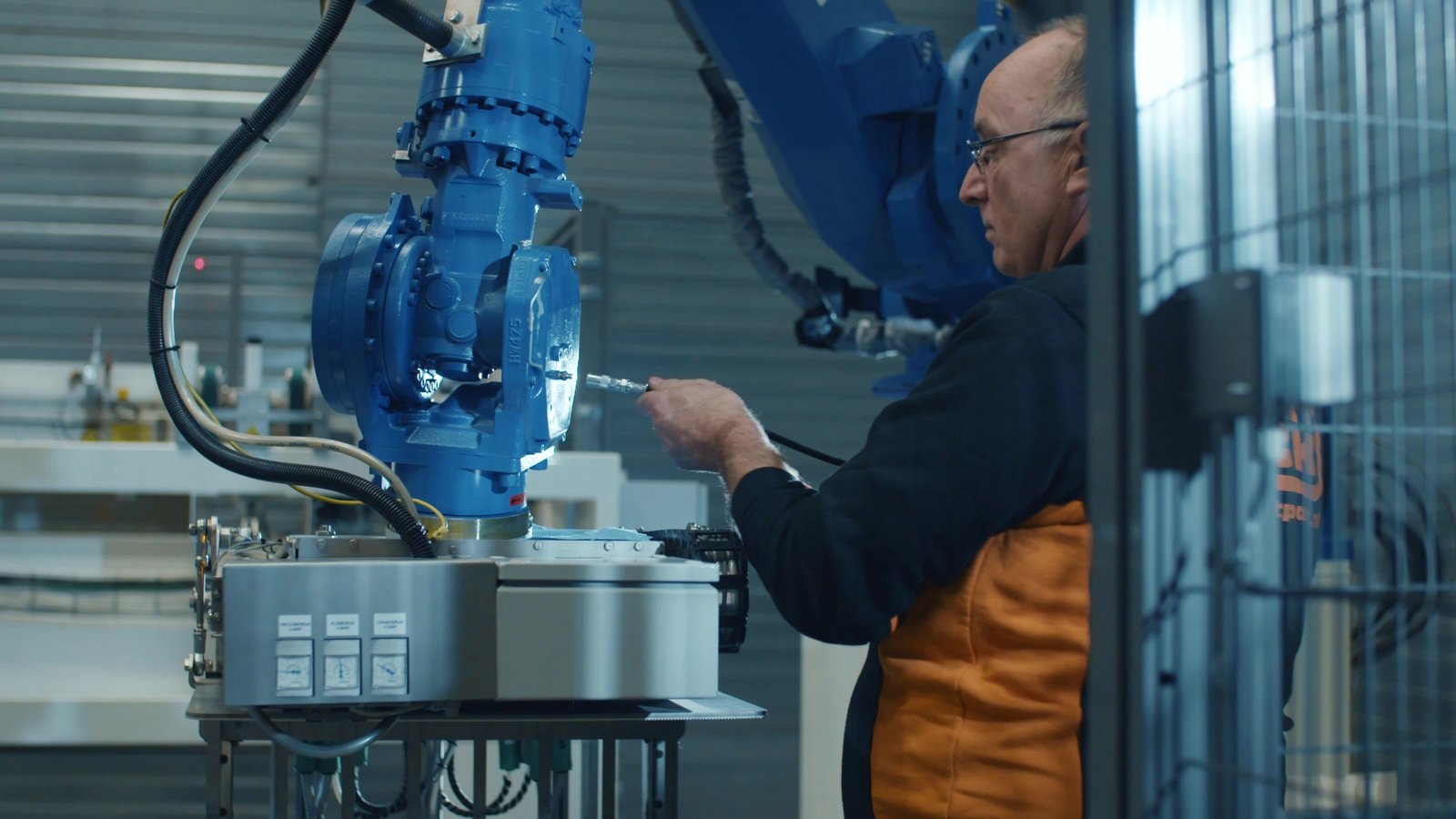

Preventive maintenance

We coordinate the frequency of preventive maintenance with you. Our qualified and experienced technicians carry out maintenance according to applicable instructions and specifications to ensure that your machine stays in optimum condition for high productivity.

Predictive maintenance

Optionally, the supplied machine can be equipped with maintenance software, which records the machine load, which is then used to determine which components need to be replaced. This recording system prevents early or late component replacements and unnecessary costs.

Overhaul and repair

We are the right partner when it comes to overhauling robotic grippers. Following an extensive inspection, the parts that qualify for overhaul are determined. After consulting with you, the overhaul will take place on site or at our workshop in Zwolle. The premise is that the overhauled part is as good as new and can be used for many years to come after being repaired.

Upgrade

Technology does not stand still! New developments, options and solutions are continuously put on the market. With the new state-of-the-art technology, it is often possible to "upgrade" your outdated machine. Modern technologies can help improve your machine for higher capacity and/or efficiency.