Case study: Bolletje case loader

Packing Elopaks "Schuddebuikjes" into cases

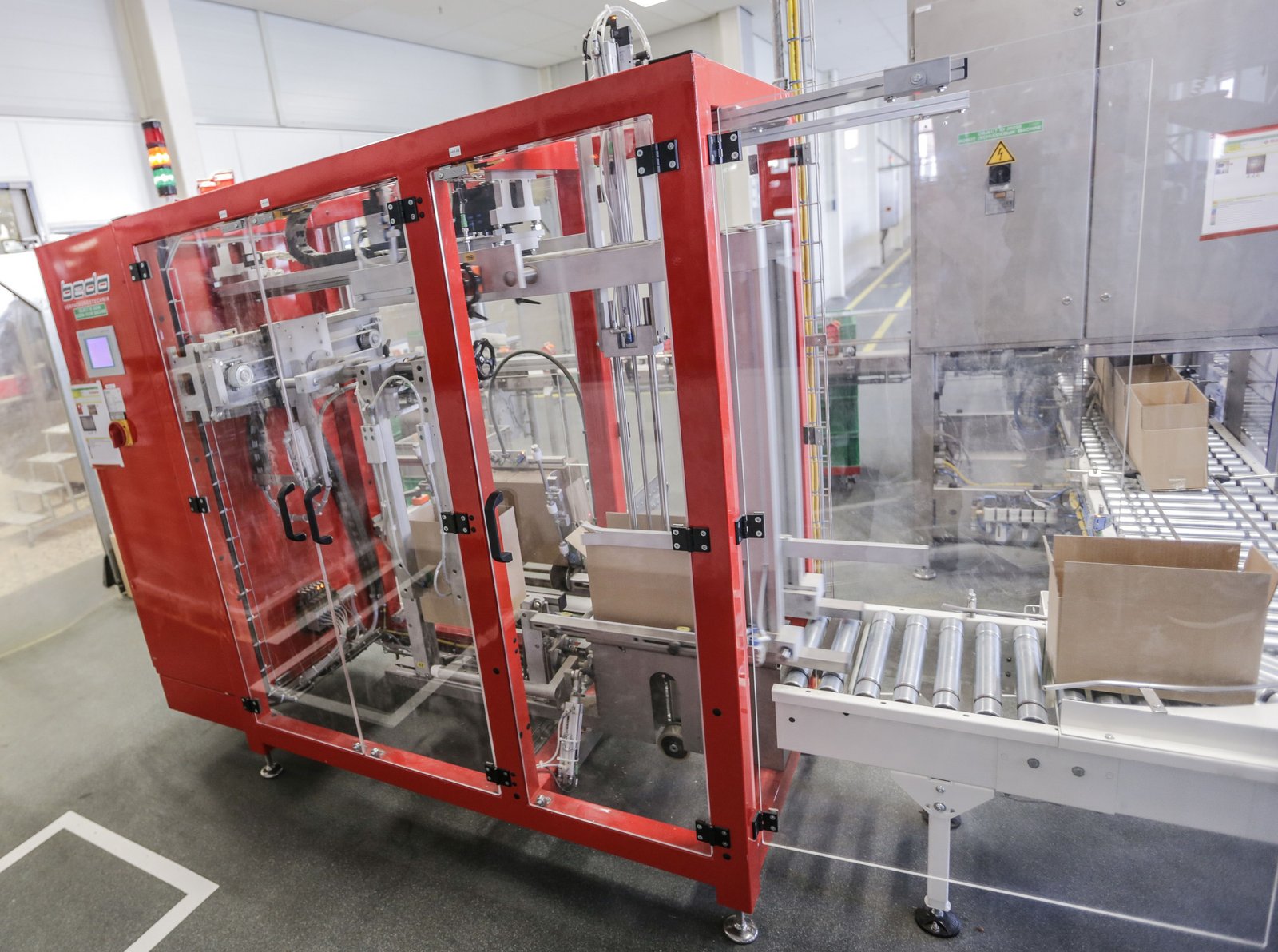

These case are erected by an automatic bedo case erector machine Type VA1112E and then transported to the robotic case loader.

The single packs are transported on a single lane conveyor in upright and oriented position, with the caps facing forward or backwards.

The advantages of Robertpack for you as customer:

- More than 45 years of experience

- A team of experts in our professional field

- Our own mechanical and software engineering

- Customisation and top quality

- Very good service

- A solid and reliable partner

- Solutions from single cells to complete final packaging lines