Robot Pick & Place systems for food and non-food

Do you want to carry out repetitive Pick & Place operations more quickly and efficiently?

Repetitive Pick & Place operations within your production process can be easily taken over by a robot. This improves your productivity and flexibility. We have a wealth of experience in developing and delivering robot Pick & Place systems for very quickly picking and placing all sorts of products.

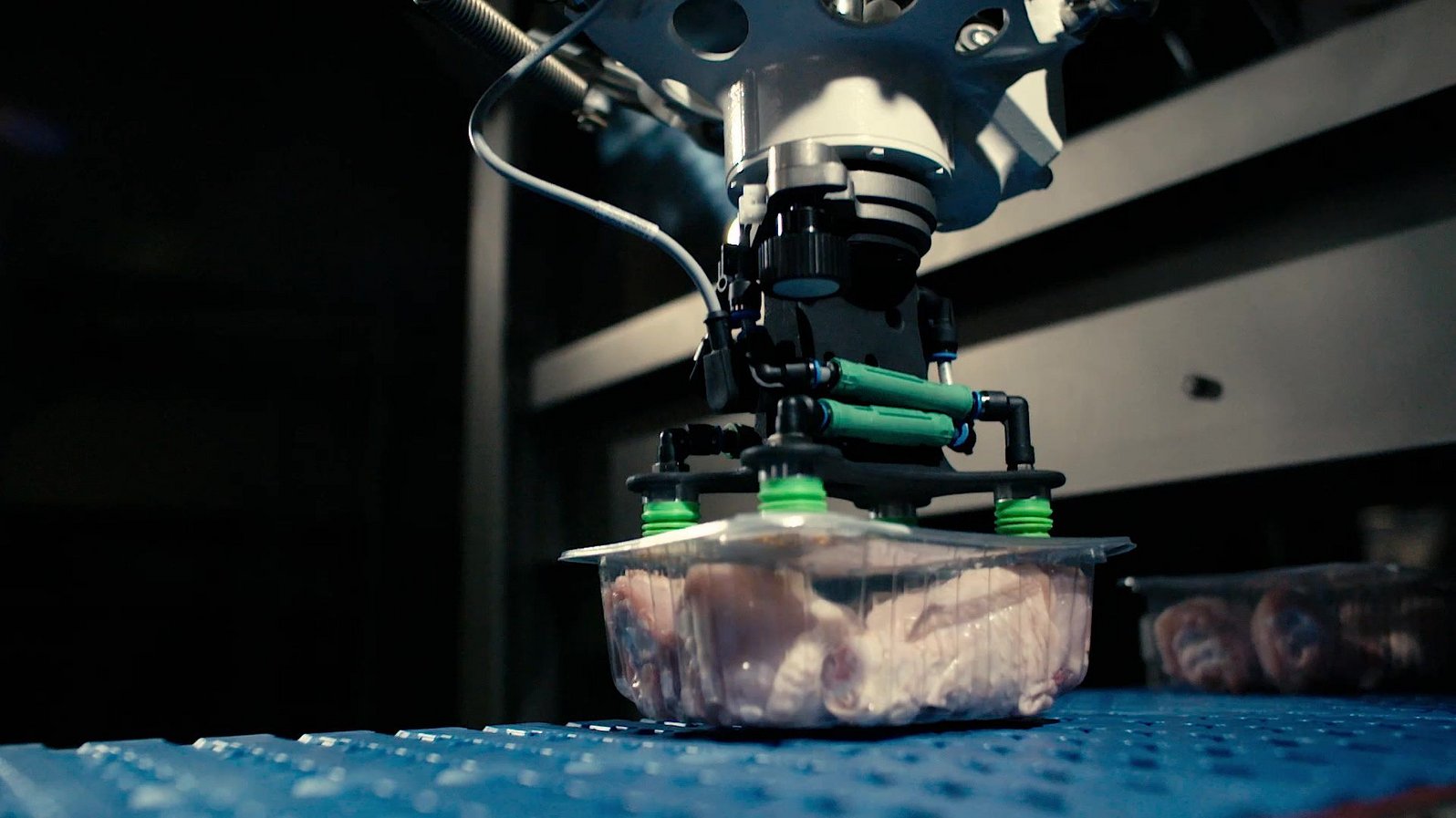

Pick & Place robots pick up your product with a (product-specific) clamp gripper or through vacuum technology. This depends on your product.

Our robot Pick & Place systems are fitted with vision & line tracking, and this increases the productivity considerably. Through the vision & line tracking system the robot recognises your product and its position. This allows your product to be very quickly moved from, for example, a moving conveyor belt to a different desired point without being damaged.

Tailor-made solutions!

We have a suitable solution for every company, and each robot Pick & Place system is designed fully in accordance with your specific needs. Our systems are suitable for various applications, such as tray/cassette loading, case loading, crate loading, etc., but also for loading flow packers, thermoformers, etc.

They are available in stainless steel or coated finish. The integration of a bedo® case erector and a case sealer is possible as well as quick-change systems. You can easily expand your robot Pick & Place system with a crate stacker and de-stacker and a robot palletising system.

The advantages of Robertpack for you as customer:

- More than 45 years of experience

- A team of experts in our professional field

- Our own mechanical and software engineering

- Customisation and top quality

- Very good service

- A solid and reliable partner

- Solutions from single cells to complete final packaging lines

Your advantages from using Robertpack robot Pick & Place cells:

- Quicker: Robots with a capacity of up to 120 picks per minute/per robot

- Flexible: Modular design for addition of multiple robots

- Suitable for various applications: tray/cassette loading, case loading, crate loading, etc., but also for loading flow packers, thermoformers, etc.

- Vision & line tracking makes your production more efficient and increases your productivity

- Also wet areas and (optionally) robots can be cleaned with foam

- Gripper systems and hardware and software engineering are developed in-house.