Robertpack in the bakery and pastry industry

Improvement in efficiency and optimisation of your packaging process: you save time and money!

Heavy physical, boring and monotonous work can easily be taken over by robots. For many years now we have been delivering robotic systems to (industrial) bakeries for various applications such as handling baking trays, packing petit fours in boxes or palletising cases of crackers. They have chosen the expertise, years of experience and provision of the most suitable solution and good service of Robertpack.

Our years of expertise? Tailor-made solutions for:

- Packing various types of bread and pastries

- Automatic loading of packaging machines; flow packers, thermoformers and top sealers

- Case packing in cases or crates, SRP Packaging

- Depalletising and palletising of the cases and crates

- Robot Pick & Place

- Robot Handling

- bedo case packaging line

Your advantages from using robots:

- Favourable payback period.

- Promotes good working conditions.

- Maximum freedom of movement.

- High capacity and efficiency; one robot can often take care of the packaging of several lines.

- Flexible due to quick-change grippers.

- Highly reliable technology.

The advantages of Robertpack for you as customer:

- More than 45 years of experience.

- A team of experts in our professional field.

- Our own mechanical and software engineering.

- Custom-made and top quality.

- Very good service.

- A solid and reliable partner.

- Solutions from single cells to complete final packaging lines.

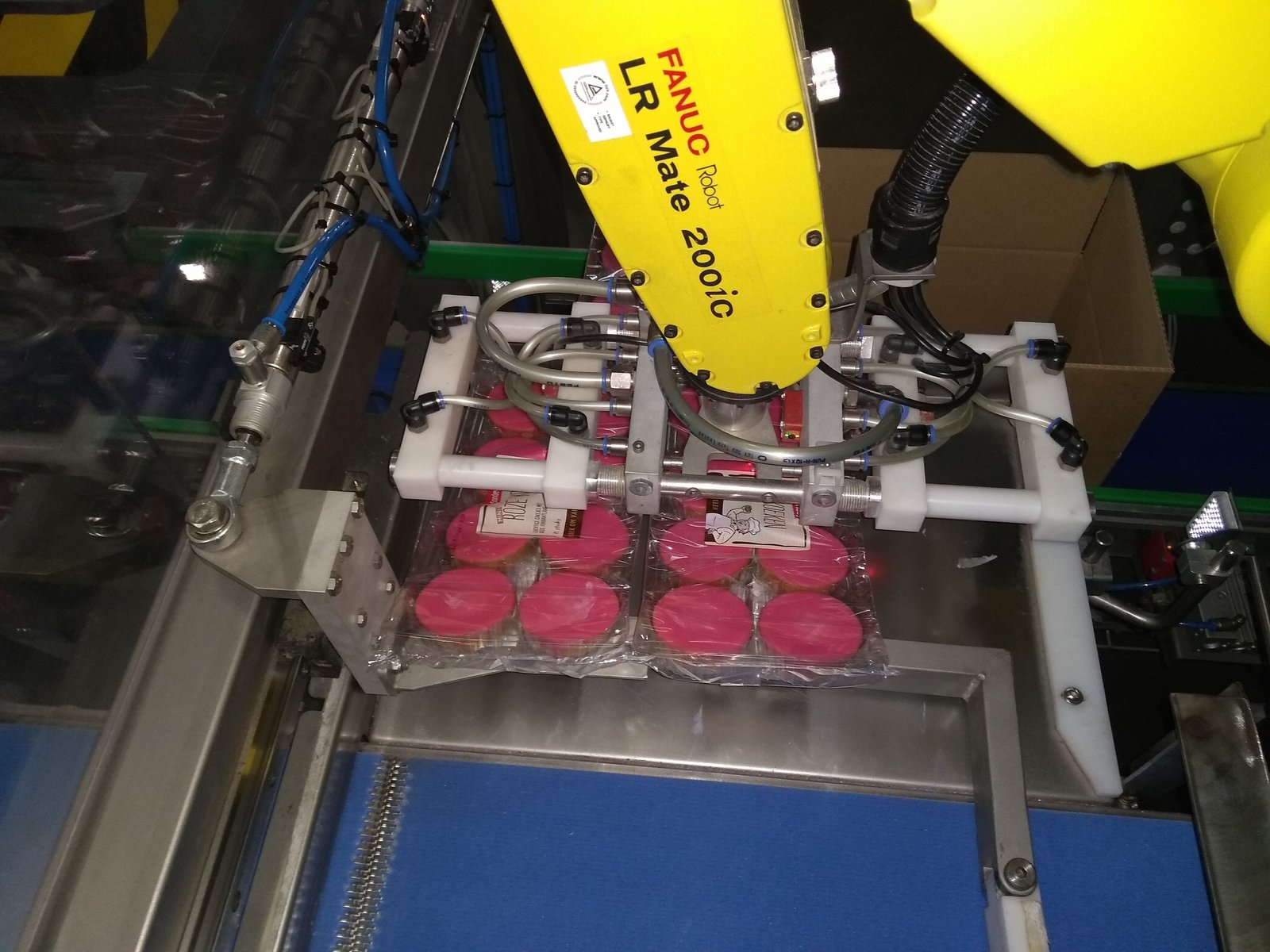

Packing Elopaks "Schuddebuikjes" into cases

The cases are erected by an automatic bedo case erector Type VA1112E and then fed to the robot case loader. The single packs are transported on a single lane conveyor in upright and oriented position, with the caps facing forward or backwards. Using its clamp gripper, the 6-axis Fanuc LR Mate robot grips the first 4 packs and places them upright into the case. Then it repeats the same process with the second 4. The movement of the packs in the case can be easily controlled by the 6-axis robot control.